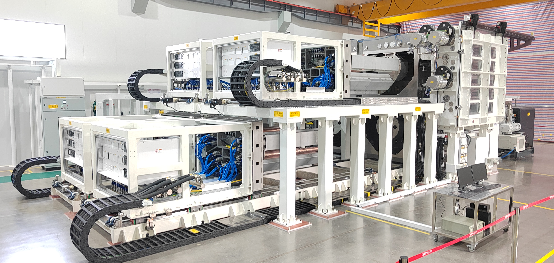

Independent R & D of Roll-To-Roll Double-Sided Copper Foil Magnetron Sputtering Coating Equipment

Recently, S.C's self-developed roll-to-roll double-sided copper foil magnetron sputtering coating equipment has been successfully manufactured. The success not only opens up new horizons for S.C in the market for vacuum equipment for composite current collectors, but also represents a major breakthrough for S.C in the field of special vacuum equipment for lithium-ion battery production.

Through extensive technical research by our R&D team, we have successfully produced our first roll of 4.5μm composite copper foil, with a sputtered copper film thickness of 30nm on both sides and a sheet resistance of 1.7Ω~2Ω. The production has reached a rotation speed of 30m/min, far exceeding the general market production speed of 5~12m/min. Adopting our self-developed roll-to-roll control system, this copper coating vacuum equipment has robustly produced 20,000 meters of foil, showing excellent performance in smoothness with no tear or wrinkle. In addition, our company has combined modular designs and utilized the innovative design of vacuum isolating gate valves to realize fast roll change without breaking vacuum, which increases production efficiency and achieves cost reduction and efficiency improvement in composite copper foil production.

Compared with conventional Cu foil or Al foil, composite current collector has significant competitiveness for substitution needs in various application scenarios, such as new energy vehicles, energy storage and consumer batteries, etc., due to its high safety performance, high energy density, low cost, and so on. A major innovation in key battery materials in recent years, composite current collector has the potential to be the next-generation key material for battery performance improvement and cost reduction.

In the face of the huge trend of composite current collector application in the new energy Li-ion battery industry, S.C has been accumulating knowledge of vacuum coating technology for future application and adhering to the development philosophy of "Advanced Products, Cutting-Edge Equipment". S.C will overcome the industrialization limitations of composite current collector, lead the industry and contribute to its continued growth!